+ TECHNOLOGY

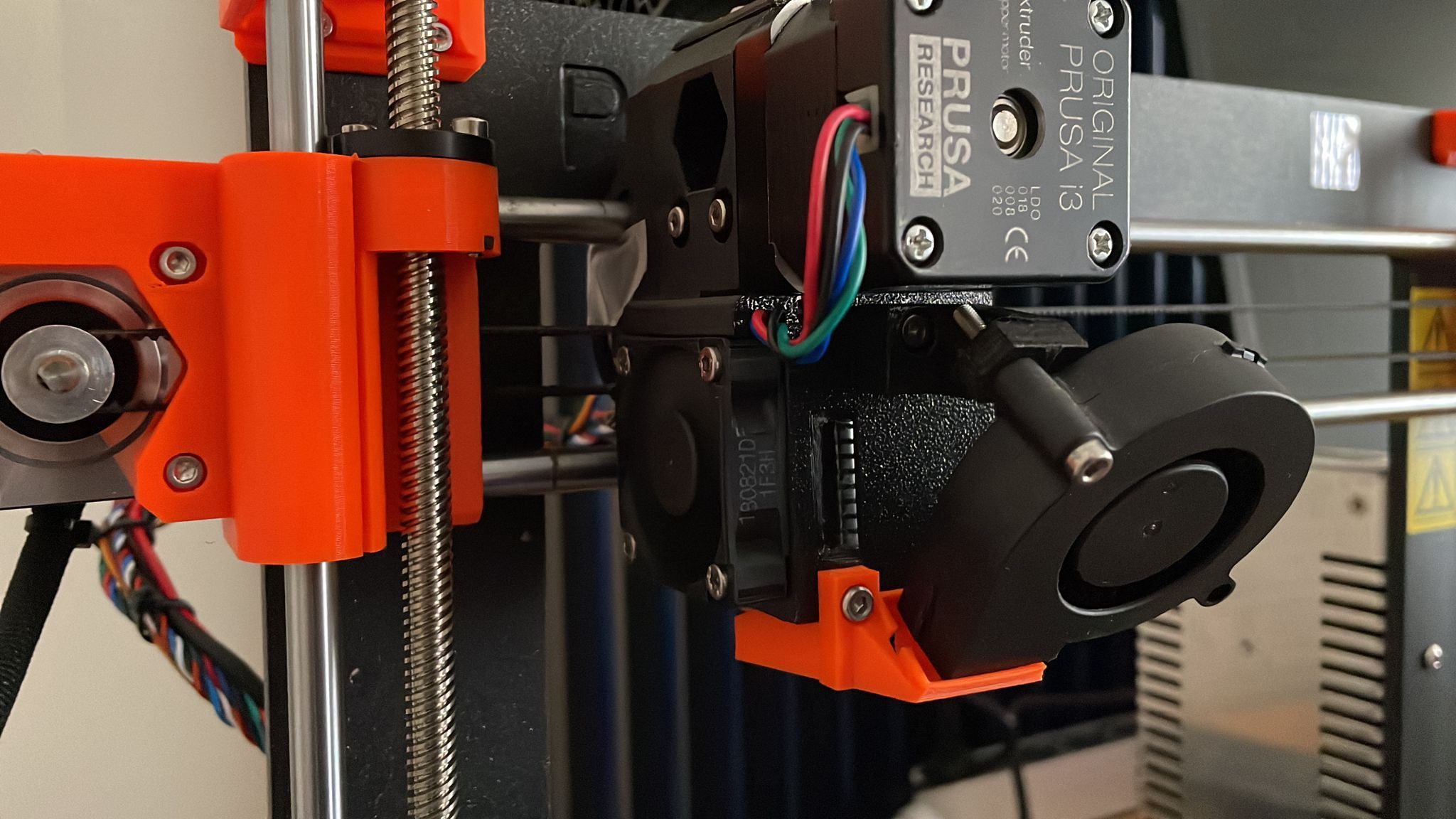

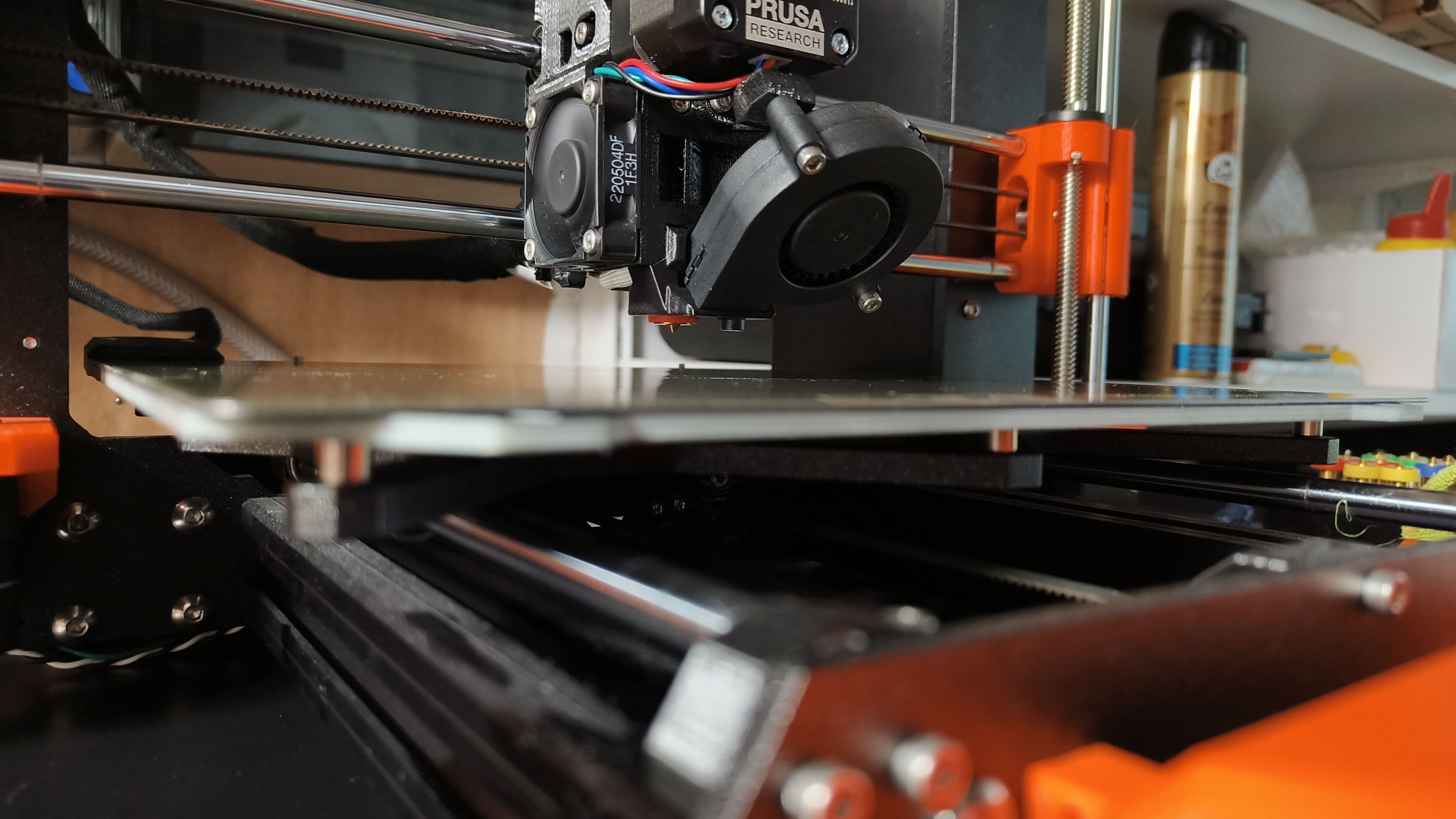

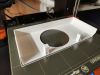

At Get It Printed we focus on functional parts and scale modelling so we chose FDM as our printing technique. FDM stands for Fused Deposition Modeling and is an additive manufacturing process in which material is deposited layer by layer at the correct positions, creating a 3D-object. The precision of this technique allows layer height as small as 0.05 millimeter, resulting in a very high level of detail.

Custom design, high details

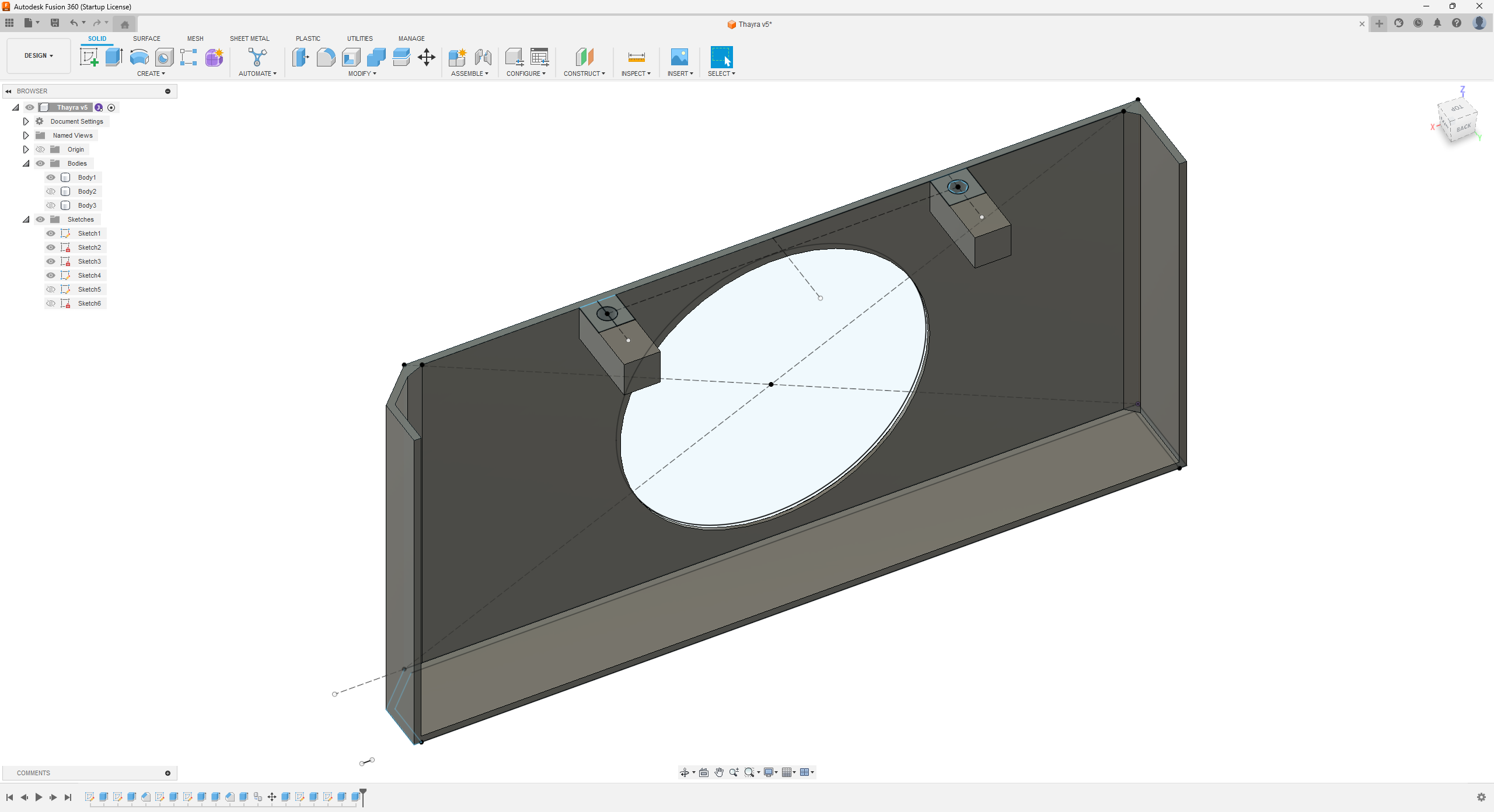

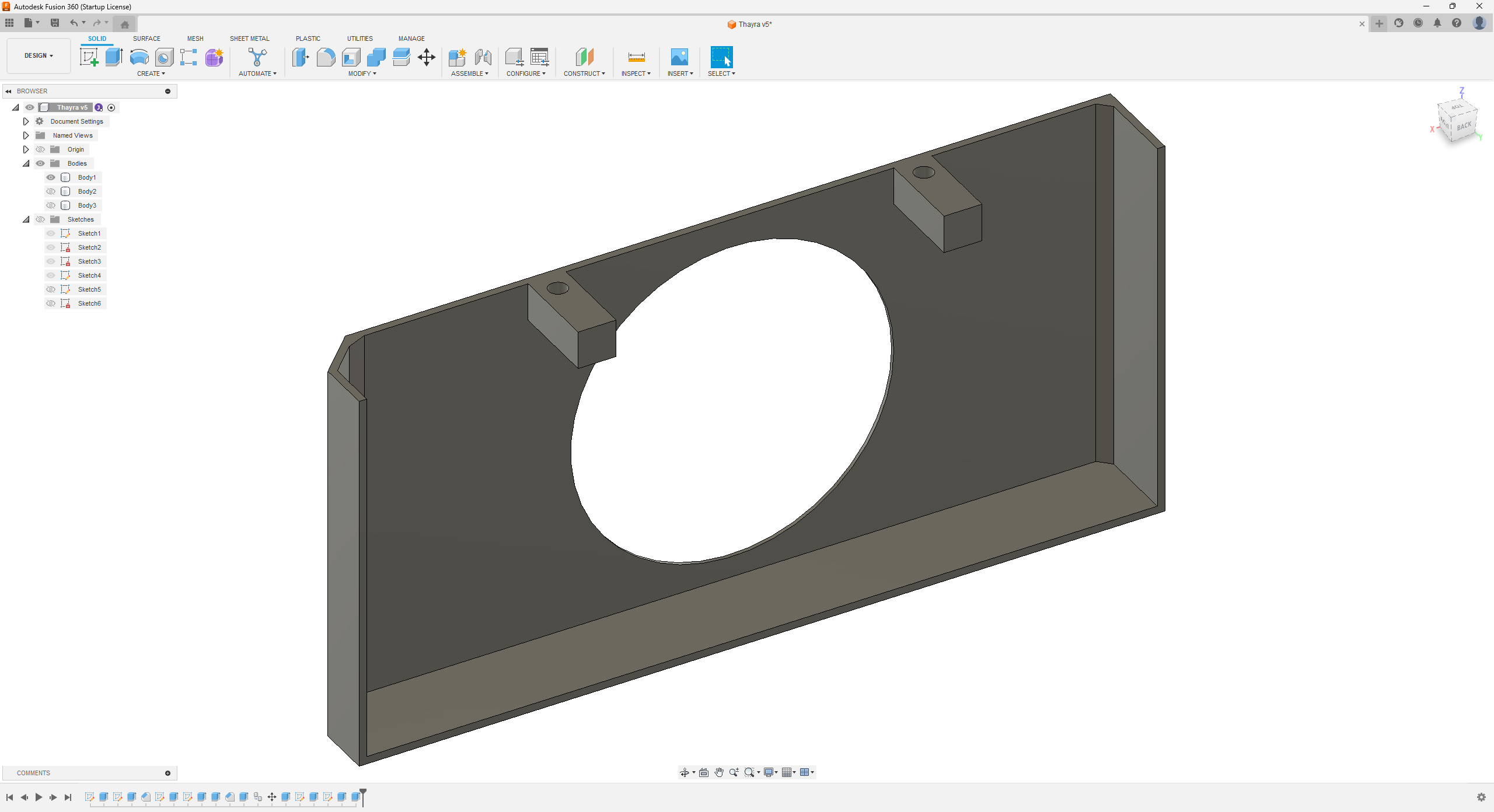

Everything starts with an idea that needs to be translated to a 3D-model. This is done using software that generates computer-aided designs (CAD, which contains the complete architecture of the model). Usually in 3D printing, STL- or OBJ-files are used (which contain only the geometry of the model). At Get It Printed we are able to process both (CAD and STL/OBJ), but in case of STL- or OBJ-files modifications are more complex.

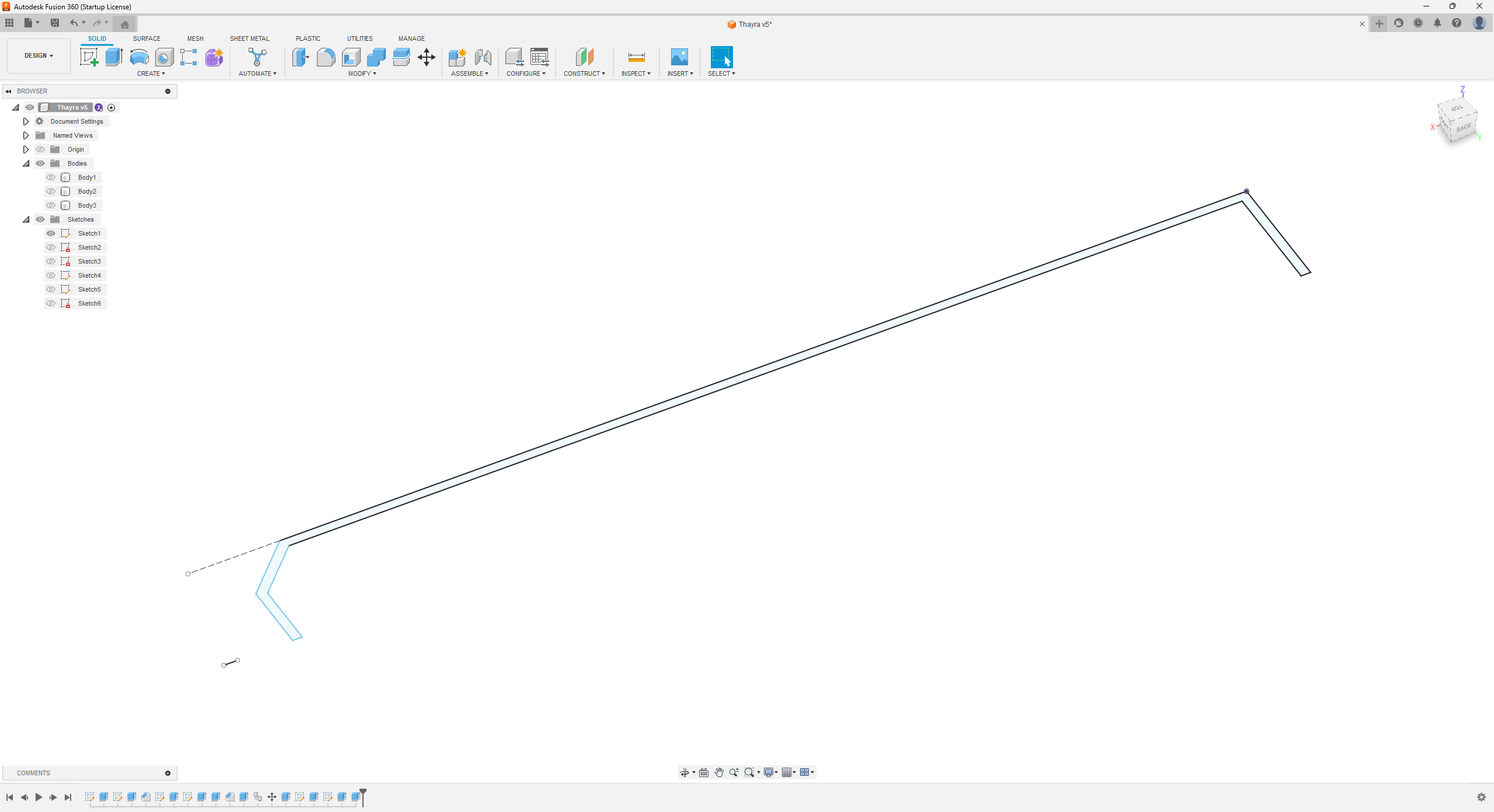

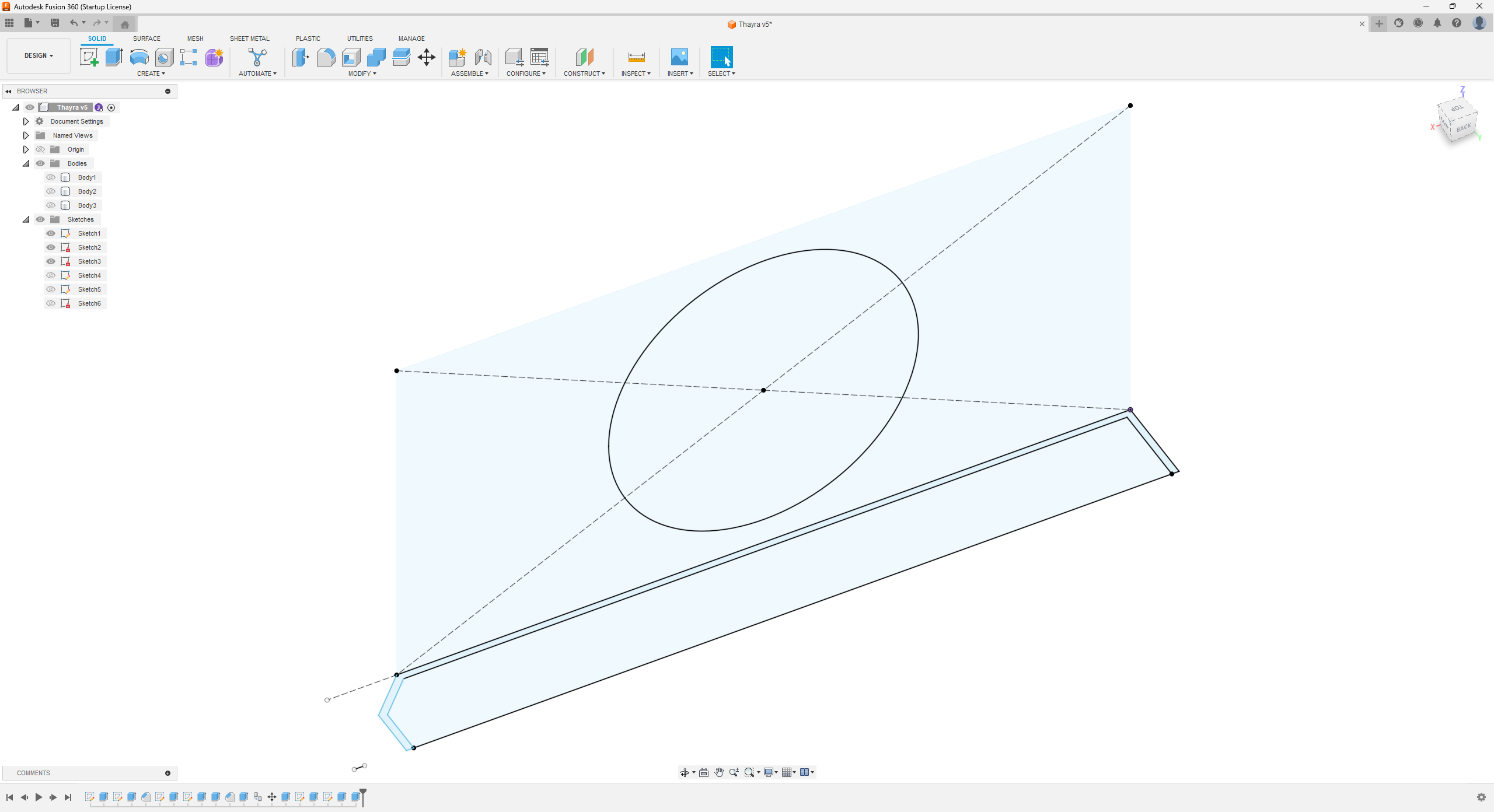

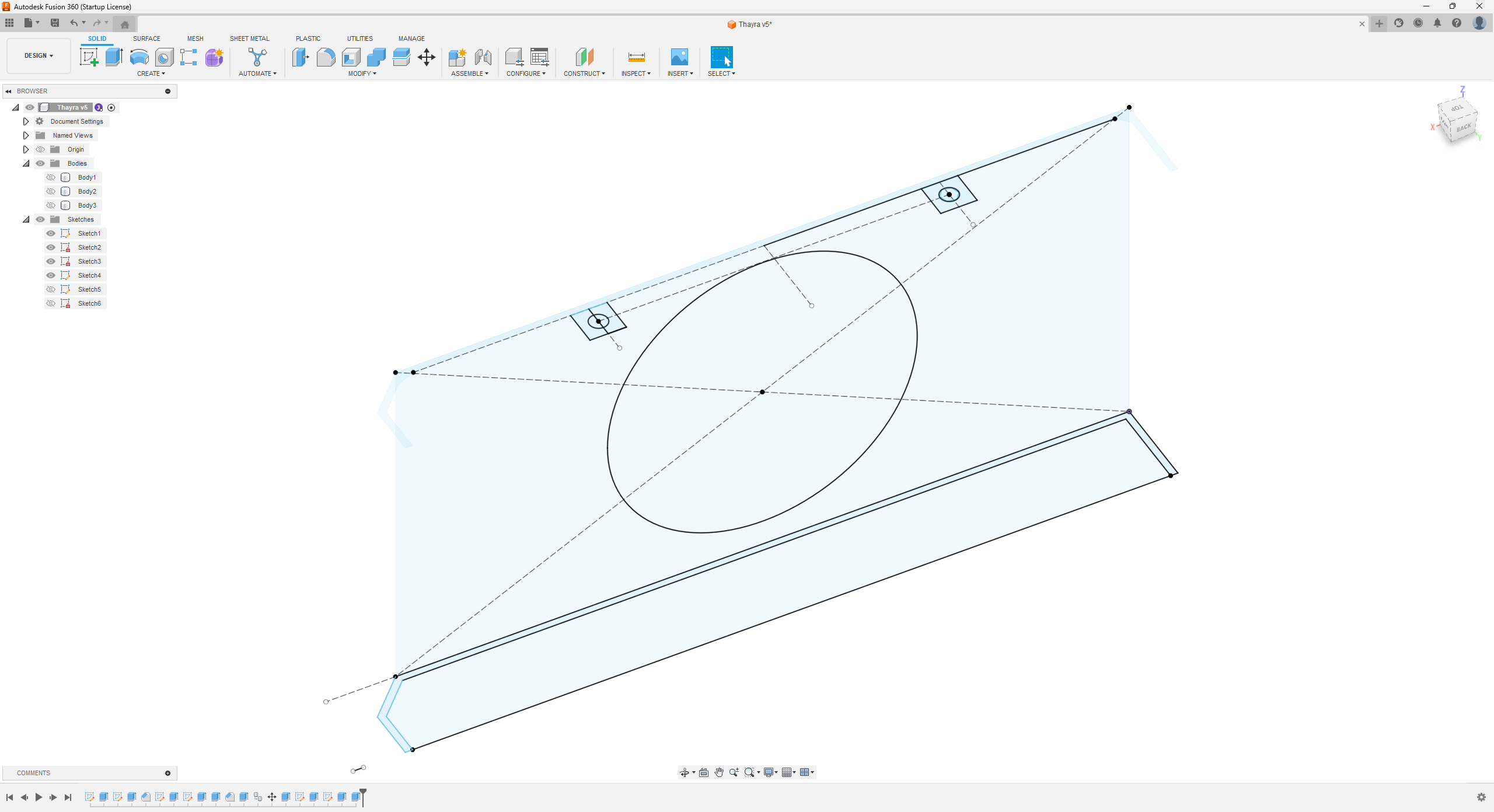

If we need to generate a 3D-model ourselves, we work with Fusion 360. The advantage of working like this is that we have control over every step of generating the 3D-model. When we design a model ourselves, we immediately take into account some important design concepts that facilitate 3D-printing of the final model.

From CAD to printable 3D-model

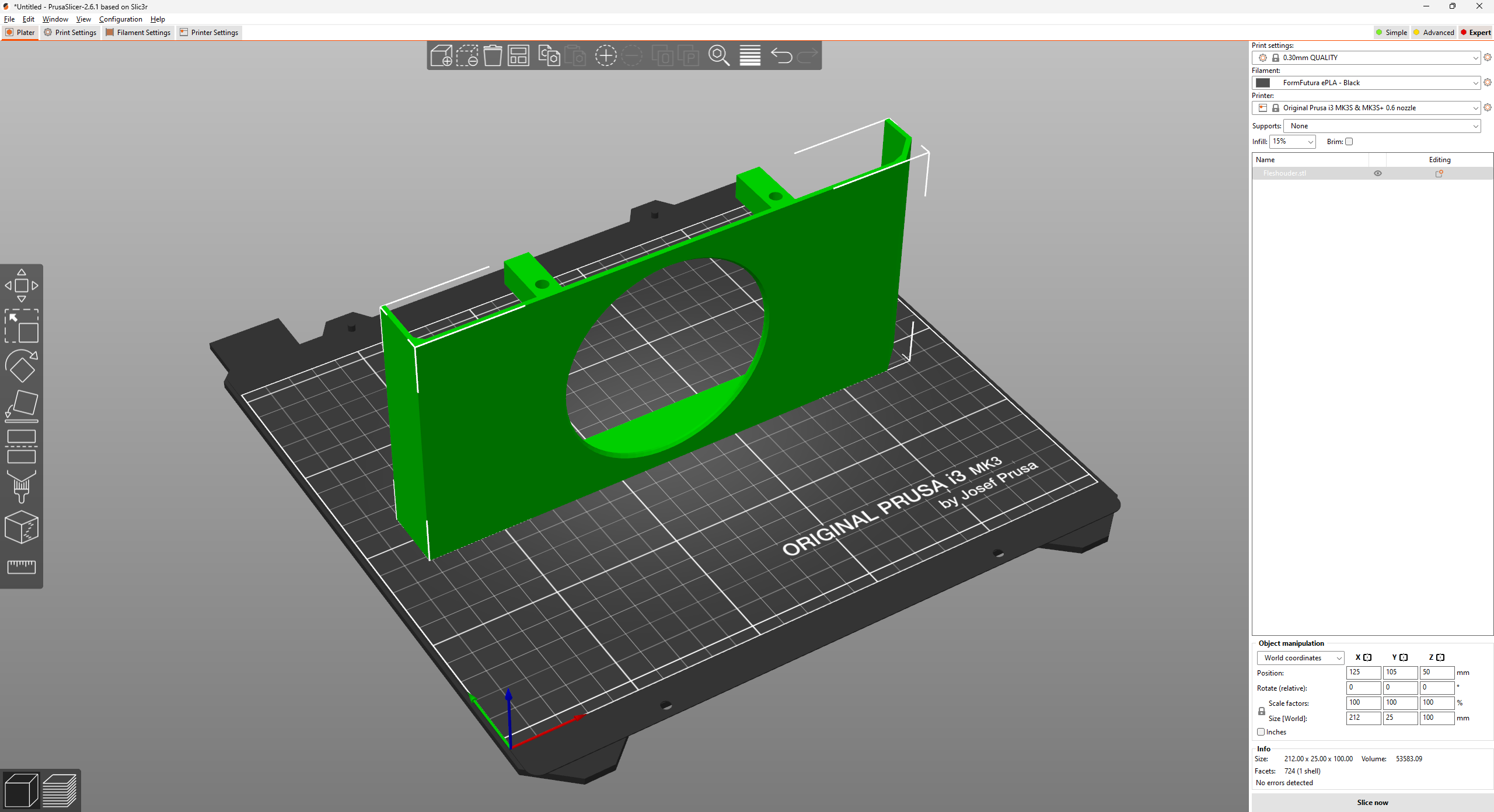

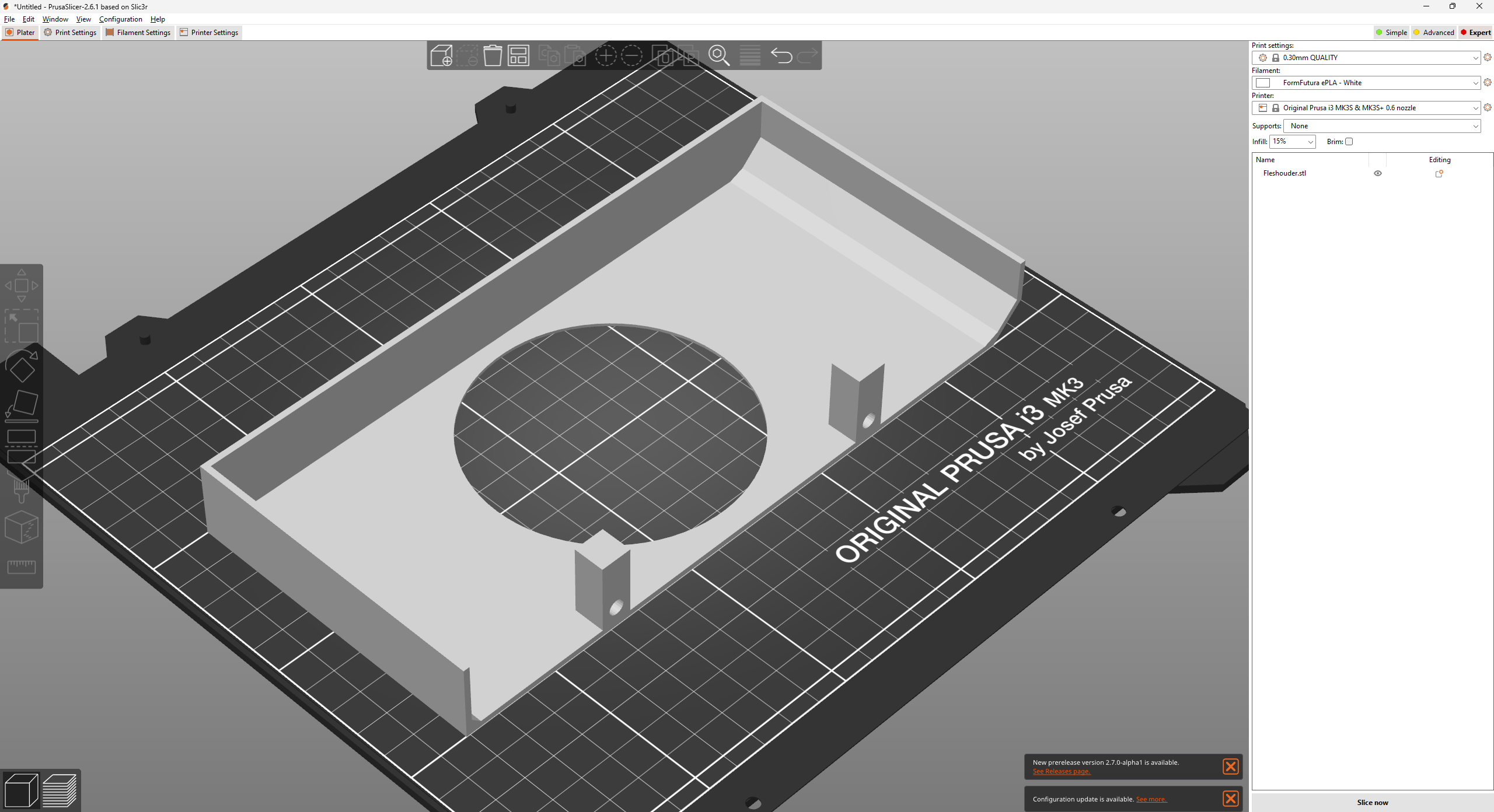

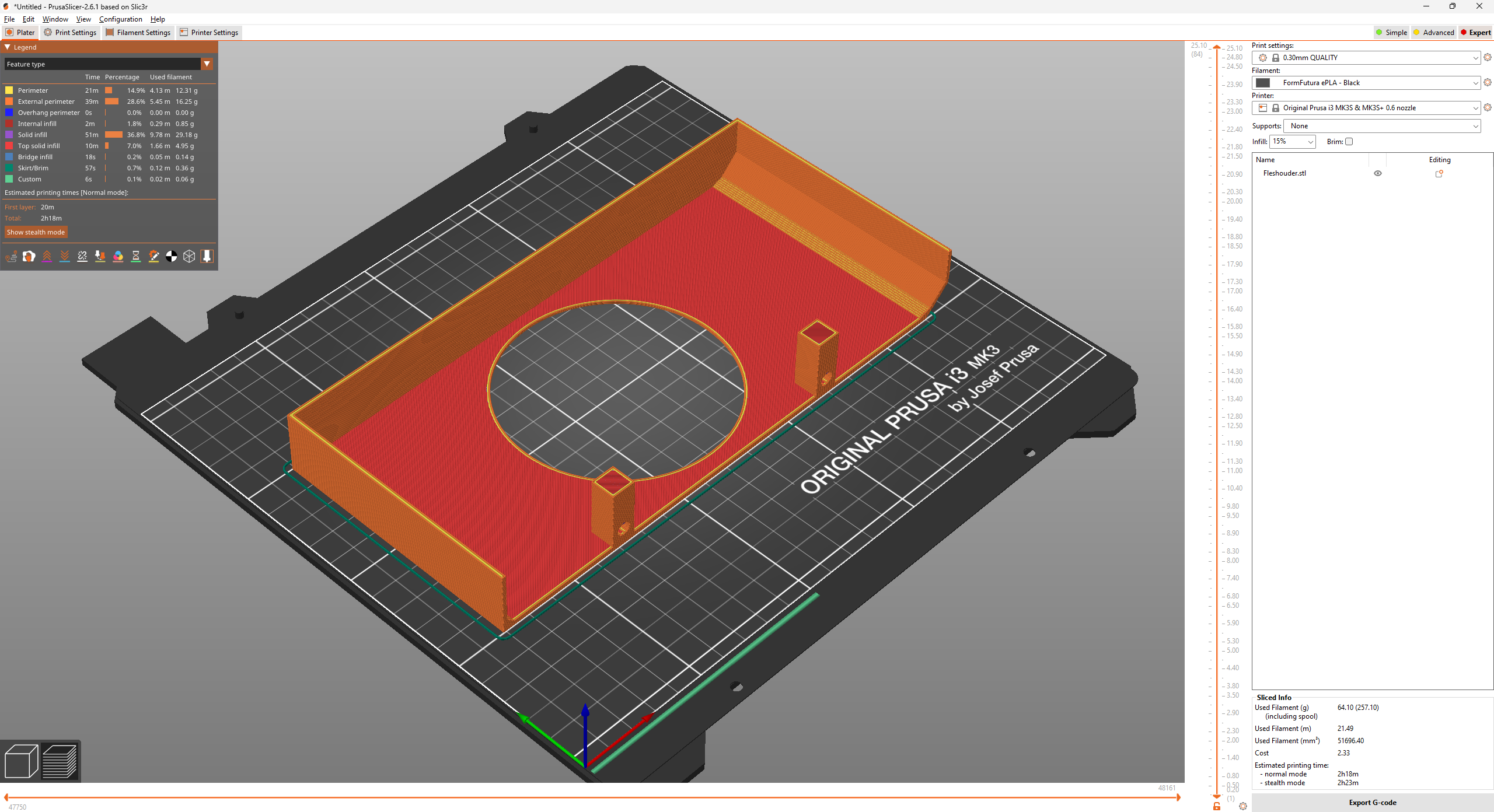

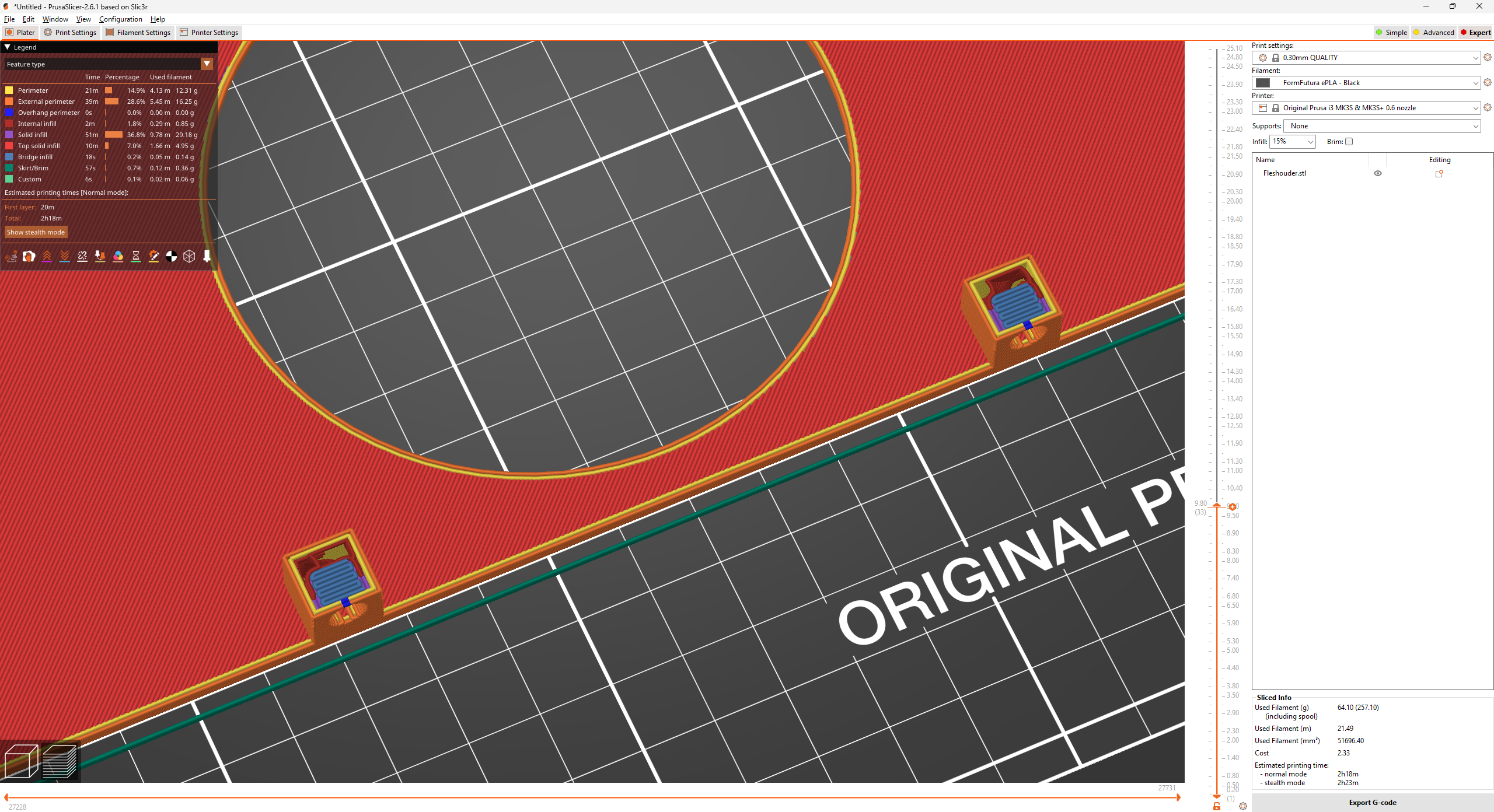

Once the 3D-model is finished, we finally export this to an STL-file as well. The reason we do this, is that the geometry of the 3D-model is run through a 2nd software package called the “slicer”. This software is also essential in the whole process of 3D-printing.

Without going into too much detail, these are some things that the slicer takes care of:

- Alignment of the 3D-model on the virtual build plate

- Calculation of settings like printing temperature, layer height, level of detail

- Generating support for parts of the model that have insufficient support to print on

- Generating a file that contains the instructions for the 3D-printer

From printable 3D-model to tangible object

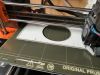

The slicer generates a file than can be transferred via the network to the 3D-printer. This file contains instructions for the 3D-printer, layer by layer: the movement in the XY-plane, temperature, amount of plastic to be extruded, etc.

The selected layer height and diameter of the nozzle, together with the other settings as configured in the slicer, will determine how long it will take before the 3D-printed object is ready. Providing a wide range of materials and colors, we are able to select an optimal combination of material, settings and design, leading to a satisfying result.